Understanding Tensile Testing for Better Metal Forming Simulations

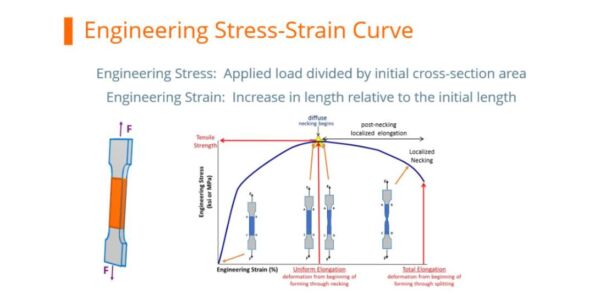

Tensile testing provides essential data for metal forming simulations, but using the wrong stress-strain model can lead to inaccurate results. Engineering stress-strain curves, based on initial measurements, don’t account for how a material changes during deformation.

For advanced high-strength steels (AHSS), precise simulations help optimize production, reduce waste, and minimize costly recuts. Converting engineering data to true stress-strain curves—or using tests like biaxial bulge testing—improves accuracy.

In our latest AHSS Insights article – which features an all-new video viewing option as well – AHSS Guidelines technical editor Danny Schaeffler shares how best to get the right inputs for your simulation. More: Tensile Testing: Engineering Stress-Strain Curves vs. True Stress-Strain Curves

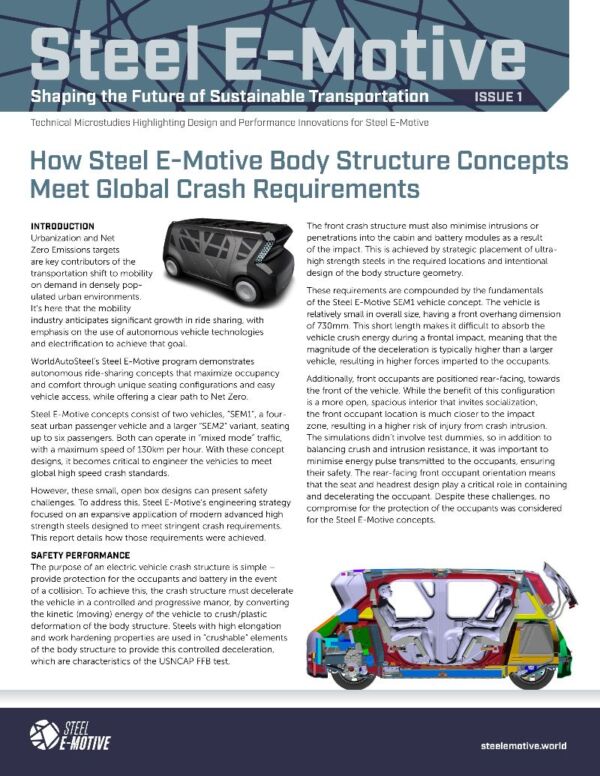

WorldAutoSteel Launches First Steel E-Motive Microstudy

WorldAutoSteel has launched its first edition of “Steel E-Motive: Shaping the Future of Sustainable Transportation,” a series of technical microstudies highlighting design and performance innovations from its flagship technical program.

The inaugural mic rost udy takes an in-depth look at how extensive front crash simulation scenarios were used on Steel E-Motive’s body structure concepts to meet stringent global crash standards, including the USNCAP 56kph FFB test and the IIHS 64kph SORB test.

rost udy takes an in-depth look at how extensive front crash simulation scenarios were used on Steel E-Motive’s body structure concepts to meet stringent global crash standards, including the USNCAP 56kph FFB test and the IIHS 64kph SORB test.

To download the complete study, “How Steel E-Motive Body Structure Concepts Meet Global Crash Requirements,” visit the report download link.

To receive to receive future issues of the SEM Microstudies, subscribe here.