Vehicle Lightweighting Kit

WorldAutoSteel members have invested over a decade in engineering projects, conducted by some of the finest engineering firms in the world, and over €80 million to make available a wealth of information in applying the latest in steel technology achievements to the mass reduction and performance improvement of vehicle body structures. The resulting reports have many patentable concepts, but they are made freely available in the public domain for use by all those in the world of vehicle design, and those aspiring to be.

At the bottom of the page is a ZIP file download that contains the following reports, projects and other tools, downloadable in one zip file to your hard drive:

|

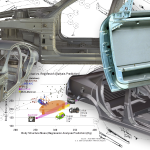

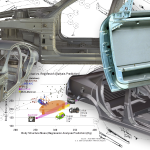

FutureSteelVehicle features steel body structure designs that reduce mass by more than 35 percent over a benchmark vehicle and reduce total life cycle emissions by nearly 70 percent. This is accomplished while meeting a broad list of global crash and durability requirements, enabling five-star safety ratings, while avoiding high-cost penalties for mass reduction |

|

UltraLight Steel Auto Body features a lightweight, efficent steel body structure that achieves impressive mass savings and significant performance improvements, while retaining affordable cost to manufacture. Demonstration hardware proved out the concept achievements in this design and engineering program. |

|

UltraLight Steel Auto Closures began as a concept development program, producing lightweight designs for doors, hoods, decklids and hatches that are up to 32% lighter than the average benchmark. The program continued to the manufacture of steel frameless door demonstration hardware that achieves dramatic results in mass reduction and performance, yet is manufacturable in high-volume at affordable costs. |

|

ULSAB-AVC (Advanced Vehicle Concepts) offers the promise that steel is the most environmentally optimal and affordable material for future generations of vehicles. The program supports this offer by demonstrating the application of new steels, advanced manufacturing processes, and innovative design concepts for U.S. mid-size and European C-Class vehicles. |

|

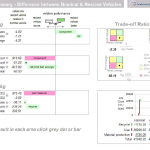

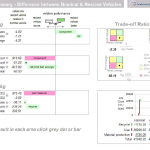

The Design Advisor allows you to quickly and accurately examine trade-offs in cost, mass and emissions at the earliest possible stage of development, when very little information is available. Constructed in a user-friendly Excel format, Design Advisor was developed by Dr. Don Malen, University of Michigan. |

|

Secondary Mass Changes in Vehicle Design focuses on means to estimate subsystem mass influence coefficients, the incremental change in subsystem mass for a unit change in gross vehicle mass. Co-authored by Dr. Don Malen, University of Michigan, and Dipl.-Ing. Dipl. Wirt.-Ing.Roland Wohlecker, Institut für Kraftfahrzeuge – RWTH Aachen University, this paper provides an indepth look at several methodologies. |

|

Mass Reduction: A report by Forschungsgesellschaft Kraftfahrwesen mbH (fka) visualizes the weight difference between steel and aluminium, and particularly the difference between recent and optimized steel designs compared to aluminium to identify the true mass potential of the body-in-white (BIW). The following two often-stated assumptions are analyzed: 1) Vehicle mass can be reduced by 25 % through the application of modern high-strength and advanced high-strength steels; and 2) Vehicle mass can be reduced by up to 50 % by the application of aluminium. |

|

Determination of Weight Elasticity of Fuel Economy for Conventional ICE Vehicles,Hybrid Vehicles and Fuel Cell Vehicles dispels exaggerated claims that are generally made about how much fuel savings are achieved by weight reduction. This study by Forschungsgesellschaft Kraftfahrwesen mbH uses carefully calculated data to assess this correlation. resulting in realistic and enlightening conclusions on what is truly possible via lightweighting alone. |

Download Vehicle Design Lightweighting Kit

Download Vehicle Design Lightweighting Kit

(Warning 354.64 MB will take approximately 10 minutes over a high speed connection)

Download Vehicle Design Lightweighting Kit

Download Vehicle Design Lightweighting Kit