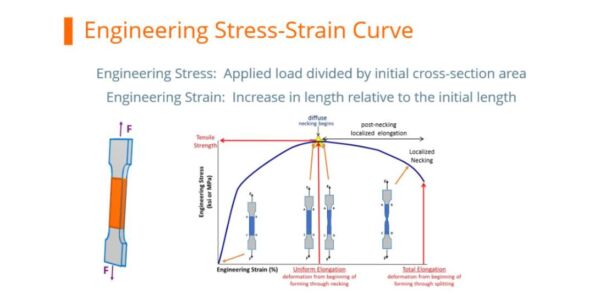

Tensile testing provides essential data for metal forming simulations, but using the wrong stress-strain model can lead to inaccurate results. Engineering stress-strain curves, based on initial measurements, don’t account for how a material changes during deformation.

For advanced high-strength steels (AHSS), precise simulations help optimize production, reduce waste, and minimize costly recuts. Converting engineering data to true stress-strain curves—or using tests like biaxial bulge testing—improves accuracy.

In our latest ASS Insights article – which now offers both written and video options – technical director Danny Schaffler shares how to get the right inputs for your simulation. More: Tensile Testing: Engineering Stress-Strain Curves vs. True Stress-Strain Curves