High-volume automotive body structures using Advanced High-Strength Steel (AHSS) grades offer the potential for low cost and weight, high strength performance, and competitive life-cycle and sustainability attributes. Reducing the number of individual parts within an automotive body structure can yield further cost, weight, and sustainability benefits without compromising performance.

WorldAutoSteel’s latest engineering demonstrator project, Steel E-Motive, delivered a clean-sheet body structure concept for a fully autonomous Mobility as a Service vehicle. The body structure design features components and sub-assemblies where the number of individual parts (i.e., stampings) have been reduced by applying fabrication methods such as hydroforming and tailor welded blanks, combined with the latest AHSS grades such as Press Hardened/Hot Formed and 3rd generation/Retained Austenite grades. Read more on our AHSS Insights Blog here: https://bit.ly/3LSQ7RY

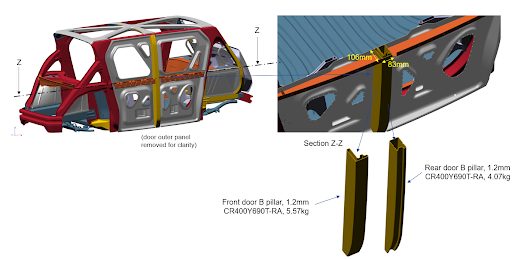

The hydroformed tube utilized for the Steel E-Motive B pillars enabled an integrated part solution, with a 10-15% cost & weight saving compared to a cold-stamped and spot-welded design.